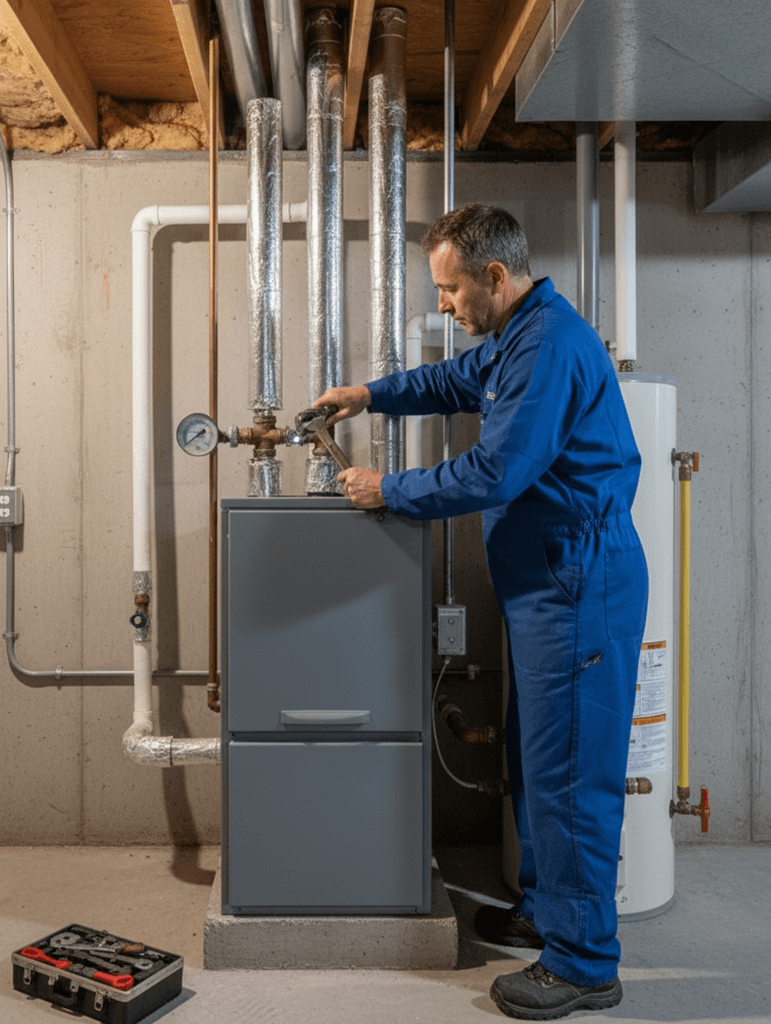

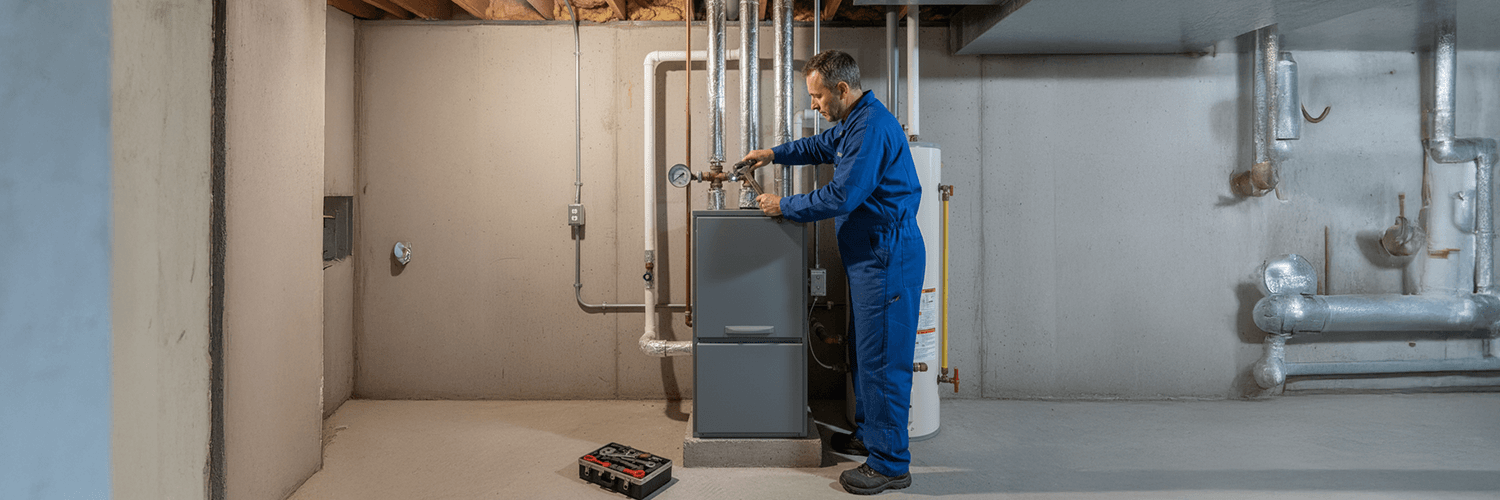

Boiler Repairs & Installations

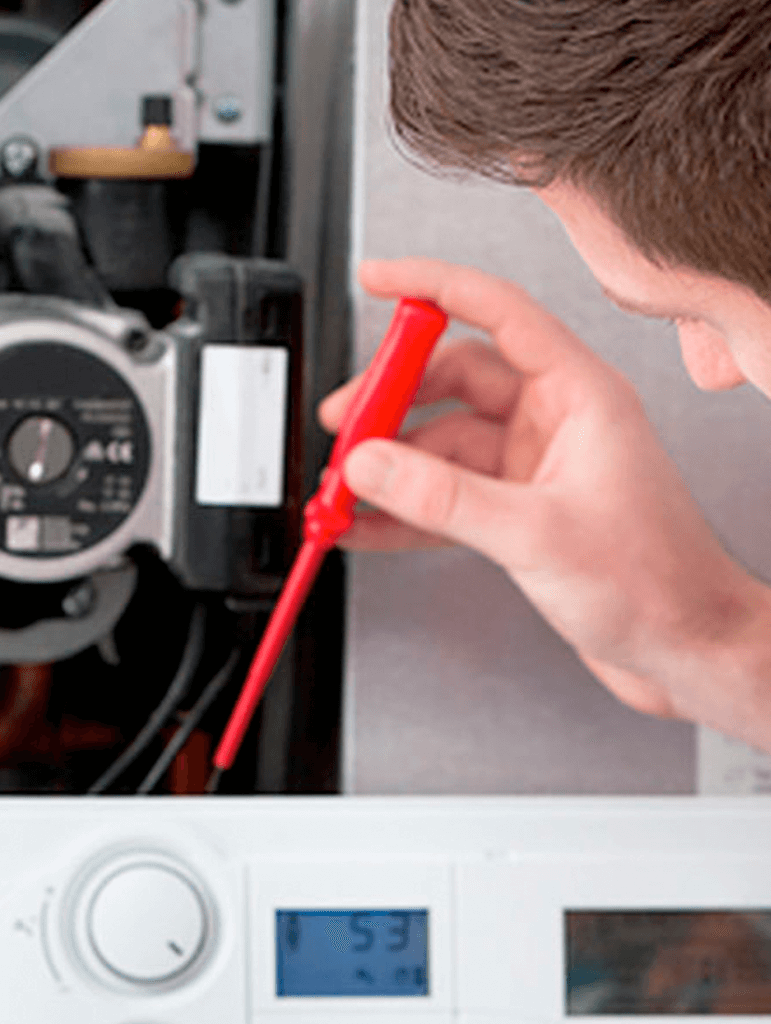

Ensure consistent warmth throughout Vancouver’s cold winters with our premier boiler services. Our experts are well-versed in the nuances of diverse boiler models, especially renowned brands like Navien and Superhot.

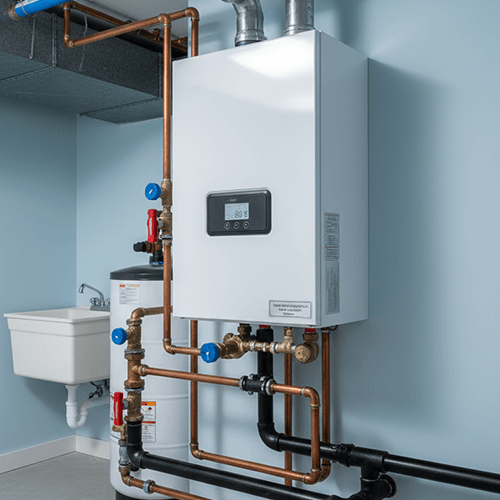

We’re dedicated to guaranteeing your water heater operates seamlessly, making your space cozy and maintaining economical energy consumption. Every tankless water heater we set up or maintain reflects our deep-rooted dedication to excellence. From vent piping and drain system checks to addressing gas leaks and conducting meticulous safety inspections, we’re the HVAC solution you’ve been searching for.

Considering a water heater replacement or repair? Look no further for top-notch heating and cooling services near you.

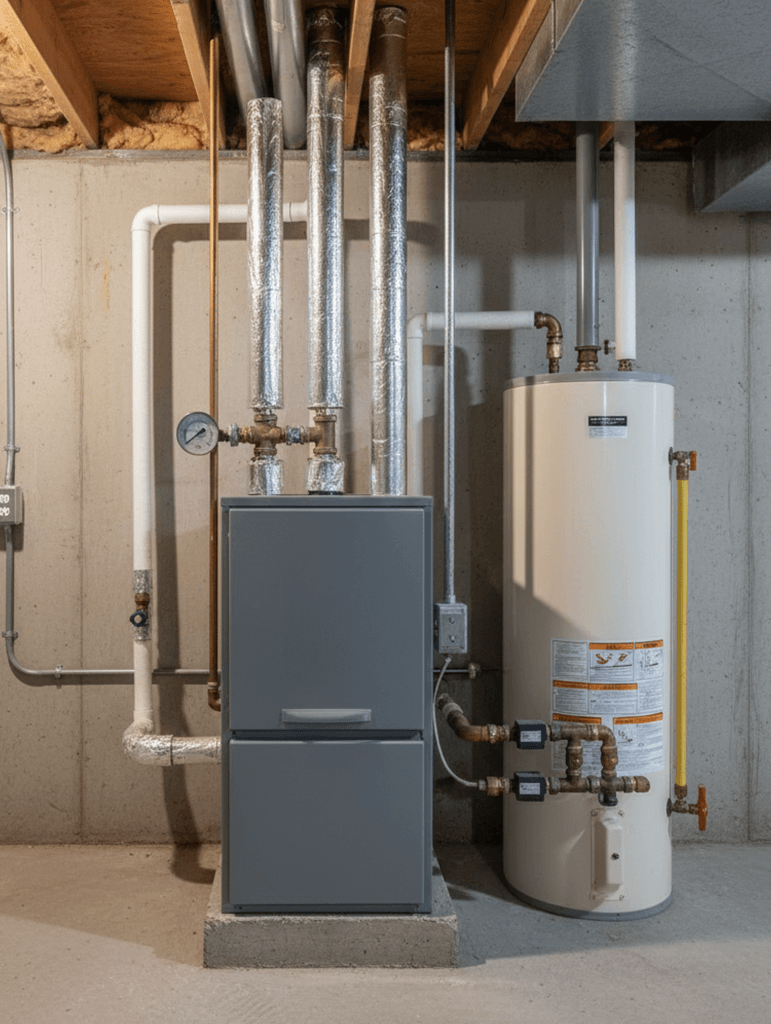

Boiler Repairs & Installations

Ensure consistent warmth throughout Vancouver’s cold winters with our premier boiler services. Our experts are well-versed in the nuances of diverse boiler models, especially renowned brands like Navien and Superhot.

We’re dedicated to guaranteeing your water heater operates seamlessly, making your space cozy and maintaining economical energy consumption. Every tankless water heater we set up or maintain reflects our deep-rooted dedication to excellence. From vent piping and drain system checks to addressing gas leaks and conducting meticulous safety inspections, we’re the HVAC solution you’ve been searching for.

Considering a water heater replacement or repair? Look no further for top-notch heating and cooling services near you.